Glycol Draft Beer System Components and its Cost

Posted by Ron on 23rd Jul 2020

Being one of the most popular draft beer systems, glycol beer chilling system is the optimal choice for any long-draw dispensing setup. In this article, we talk about its main components, how they work, and how much they cost.

What Is a Glycol System?

Glycol beer cooling system is one of the two main draft beer system options (the second one being forced-air) used in bars, pubs, tap rooms, and restaurants to maintain the cold temperature of draft beer from the walk-in cooler to the dispensing tower. This is done mainly to prevent the foam buildup as the beer travels from point A (storage) to point B (draft tower).

Glycol draft beer systems use propylene glycol as the cooling agent (hence, the name). Glycol itself is a colorless, odorless, slightly syrupy chemical compound that is a bit thicker than water. It has many applications in the food industry but, for the majority of brewers and bar owners, it’s just a component of the glycol system.

This system is mainly used for long-draw beer dispensing setups (typically, running 25 ft or longer). It works especially great in situations where you have to store beer kegs in a walk-in cooler that’s located far from the bar counter where beer is actually dispensed.

Now that we got the main idea of a glycol beer line cooling system, let’s take a look at its components and see how it all works.

How Does Glycol Beer System Work

Although glycol-cooled draft beer systems consist of dozens of components, the three main ones will always be these:

- Glycol power pack

- Trunkline

- Beer tower

Now, let’s examine each one of these components and see what their role in the process is.

Glycol power pack

Glycol power pack also known as glycol chiller is the heart of the glycol tap system. It is essentially a commercial refrigeration unit designed to pump and circulate glycol through the system thus maintaining the proper temperature.

A power pack consists of the following parts:

- Compressor

- Evaporator fan

- Thermostat (to regulate the temperature)

- Glycol reservoir with a coil (contains cooling refrigerant)

- Supply and return lines

The coil contains a refrigerant to cool the glycol in the reservoir. The circulation pump runs continuously forcing the glycol through the supply line. The compressor runs on and off as necessary to maintain the temperature that’s been set on the thermostat.

Trunk line

If the power pack is the heart of the draft beer glycol system, then the trunk line is its blood vessel. The trunk line itself is a bunch of beer lines (usually, from 4 to 10) sandwiched around a pair of glycol refrigeration lines all of which are wrapped in foil and bound together with some insulation on top.

One glycol line is outbound extending from the power pack to the beer tower while the other returns from the beer tower back to the glycol power pack.

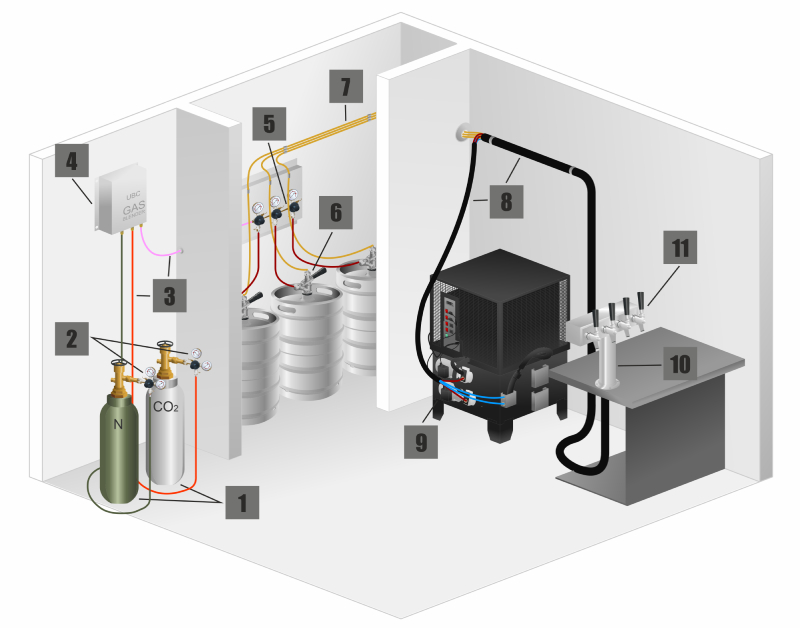

Each product line of the trunk line is hooked up to a unique beer keg stored in the walk-in cooler. The kegs are connected to CO2 or nitrogen cylinders through a series of gas blenders and pressure regulators.

To put it simply, the trunk line provides a sort of conduit of beer product lines connecting kegs of beer in the walk-in cooler to each respective faucet of the draft beer tower while also housing sealed refrigeration lines running from the power pack to the tower in a continuous loop.

The assembly of product lines and glycol lines is wrapped in a shield of foam and encased in a plastic waterproof jacket. The waterproof jacket is rather flexible and can be easily manipulated.

As for the installation, glycol draft beer lines are usually installed overhead or under the floor. If they are installed overhead, the exposed downward trunk lines would be generally housed in a combination of PVC tubing and a decorative finish. When installed under the floor, the product lines are run through a section of PVC tubing.

Beer tower

The easiest-to-explain part of the glycol beer chiller system since it’s the only element that’s “on the surface”. Beer lines are attached to a shank or faucet that’s inside the beer tower. All you have to do then is pull the lever called “tap handle” and pour some fresh, cold beer.

From a customer’s point of view, this is where beer comes from but we now know that it has to come a long way before it reaches the draft tower in your bar counter area.

Glycol draft system in a nutshell: how it all works

The power pack pushes refrigeration (glycol) through the center of the trunk line. The trunk line contains up to four glycol lines:

- outbound glycol line(s) (runs from the power pack to the tower)

- return glycol line(s) (enables the refrigerant to complete the cycle and become re-chilled)

Refrigerant lines are there to keep all of the surrounding beer lines temperature-controlled from point A (storage) to point B (where the beer is dispensed).

The ultimate goal of the whole glycol draft beer cooling system is to transport the beer from the walk-in cooler over a significant distance to the beer tower while maintaining a constant beer temperature of 36-38 degrees Fahrenheit (2-3 degrees Celsius).

Commonly, full system setup looks like this - however, multiple variations are possible.

How much does it all cost?

Below you can find an average market price of each unit. The price depends on the brand and specifications of each unit.

1. CO2 & Nitrogen cylinders - $65-80 USD

2. Primary gas regulators - $30-70 USD

3. Gas line - $1 USD per foot

4. Gas blender - $1000 - 1500 USD

5. Secondary gas regulators - $45 -250 USD

6. Keg coupler - $30 - 100 USD

7. Beer line - $0.5 - 1 USD per foot

8. Trunkline - $5 - 7 USD per foot

9. Glycol power pack - $800 - 5500 USD

10. Draft beer tower - $100 - 2500 USD

11. Faucets - $15 - 70 USD