Beer Engine: Building Instructions, How to Use It and Why

Posted by Ron on 15th Aug 2022

If you like drinking cask ales, you probably already know what a beer engine is. This wonderful little device brings us back to the good old days when life was simpler and beer was more… tasteful!

Despite being called an “engine”, this device is actually much simpler than it seems. Here in this article, we’ll show you how to build and use a cask beer engine in your home bar.

How Does a Beer Engine Work?

These days, draft beer is typically poured from a keg. In this type of system, CO2 (or nitrogen) is used to pressurize a keg and then push the beer through the tap. However, it wasn't always done this way.

Back in the old days, beer was pulled from a cask using a hand pump or a beer engine. So, what is a beer engine? It’s a simple mechanism that draws beer directly from a cask ale keg.

In a standard configuration, casks reside on a stillage. Instead of CO2 or another beer gas, they have a hole for common air. It makes its way inside the cask to replace the beer while the beer is drawn through a tap, which is hammered in with a rubber mallet (hence, the term “tap the beer”).

The beer line connects the cask with a hand-pull beer pump engine (aka beer engine cylinder). This device has a cylinder with a piston inside. When the handle is pulled down, the beer is drawn out of the cask into the glass. As you can see, there is no magic here - just basic laws of physics.

Beer Engine Parts and Components

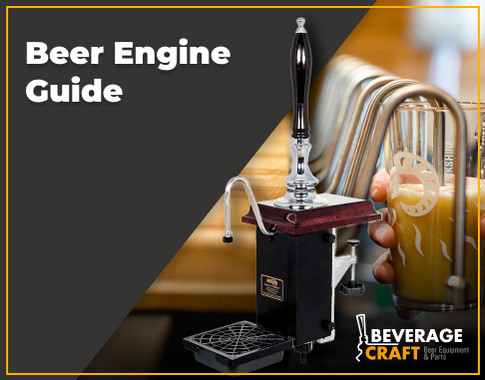

A beer engine is usually sold in the assembled form since this is how most homebrewers like to have it. However, even such a simple device does consist of various parts. Here are the key beer engine parts (top to bottom):

- Pump handle

- Swan-neck nozzle

- Sparkler

- Cylinder and piston

- Beer engine check valve

- Drip tray

- Beer line (from the cask)

The mechanics of a beer engine are rather straightforward. The airtight piston chamber is at the heart of it all. When you pull the beer engine handle, beer is simply drawn from the cask into the piston. To get a strong, foam-free flow, you may need to pull a few times, depending on the length of the beer line.

Beer engines are generally reliable devices and rarely break down. However, some parts need replacement due to wear and tear. For a wide variety of beer engine replacement parts, be sure to visit the following category at Beverage Craft website.

How to Build a Beer Engine and Connect It to a Cask Keg?

Building a DIY beer engine is hardly more difficult than an average DIY project. The tools you are going to need are as follows:

- Cask tap

- Brewery nut

- Hop filter

- Hose tail

- 32-oz rubber mallet

- Hard spiles

- Soft spiles

- Food-safe beer line

- Cask tap downspout 2 clamps

- Hand pump & beer engine

- Cask keg (obviously)

Here’s how to set up a beer engine. Start off by cleaning the keystone and giving the shive a rub down too. Then, open the cask with a hard spile by hammering it gently with a rubber mallet (the hard spile should be replaced later with a soft spile after the keg is tapped).

Hammer the cask and tap into the keg (again, using the rubber mallet - give it a gentle, exploratory tap first and then follow it with a proper one).

After you've tapped the barrel, there will probably be some liquid coming out of the spile - to remove that, use a cloth and then replace the hard spile with a soft one. It is porous enough to let the beer breathe.

To connect the downspout, you're going to need a hop filter that should be inserted into the end of the tap. Then, put the downspout through the appropriate brewery nut and, making sure the threads are matched up, screw it on there.

Next, connect the cask ale beer engine and the hand pump. To do so, put the hop strainer in (insert a hose tail into the brewery nut and secure the connection).

Next up is the beer line, which you need to connect with the hose tail and secure with a clamp.

The final step is connecting the other end of the beer line to the cask beer engine. Again, secure the connection with another clamp. Once it’s done, you can finally tap your cask keg from either a real ale beer engine using the hand pump or directly from the downspout.

To learn more about English-style cask ale beer engine parts and components, be sure to check out this article from the Beverage Craft blog.

How to Use a Beer Engine?

Dispensing beer using a beer engine pump is not rocket science - the basic principles are the same. However, being the old-school method it is, cask ale dispensing requires a more delicate approach, especially if you’re serving this beer to your bar patrons - they call it “the proper pour”.

A standard beer engine is capable of drawing about 1/2 pint of beer per one pull of the handle. This means that two solid, strong pulls (combined with a bit of skill and practice) should be enough to fill a pint glass with 2 full draws.

Just follow these simple steps, and you’ll be pouring a perfect pint every time.

- Make sure the glasses are always clean - even the slightest stain can affect the taste

- When drawing, do it smoothly and evenly - no jerky moves

- Wait for a couple of seconds to allow the foam head to rise. Once it begins to fall, starting the second draw

- Make sure you pour a full measure of beer. This means filling the glass up to the top with minimal head (rises slightly above the glass rim)

Looking for a nice beer engine hand pump for sale? Be sure to check our selection - we’ve got plenty of devices for beer engine homebrew dispensing as well as cask ale keg parts and accessories.

Where to Buy Beer Engine in Canada and the USA?

Whether you are a cask ale enthusiast or a bar owner (or both), Beverage Craft has got every piece of cask ale equipment you may need to dispense this tasteful beverage. Looking to buy a beer engine? Not a problem!

We can offer you a gorgeous clamp-on Aston beer engine designed for dispensing real ale from a cask keg. It can be easily mounted onto the bar using a standard G-clamp and is capable of pouring up to ¼ pin per pull.

We have been a reliable draft beer equipment and beer engine supplier for almost a decade and can always guarantee you the best choice of products and reasonable pricing.